Experience and artisan passion at your service

Co-design

our expertise make the difference

One of the most distinctive and highly valued aspects of our company. With over 20 years of experience working with leather and hide, we have the ability to support, assist, and organize product development.

Together with our clients, we research and experiment with innovative and original production techniques and methods to make each new model truly unique.

Collaborative Design

Custom Design, meticulously crafted down to the smallest detail

Technical and artisanal innovation

Cutting

Precision and quality thanks to new machinery

The creation of each of our products begins with the cutting phase. Every piece of leather is meticulously inspected by our operators before being placed in the cutting machine, ensuring attention to consumption and the yield of each hide. Currently, we operate 3 cutting machines (2 automatic and one press), meeting the various quantitative and qualitative product requirements.

Thanks to the Women’s Entrepreneurship Grant, we have invested in new equipment, machines, and state-of-the-art software

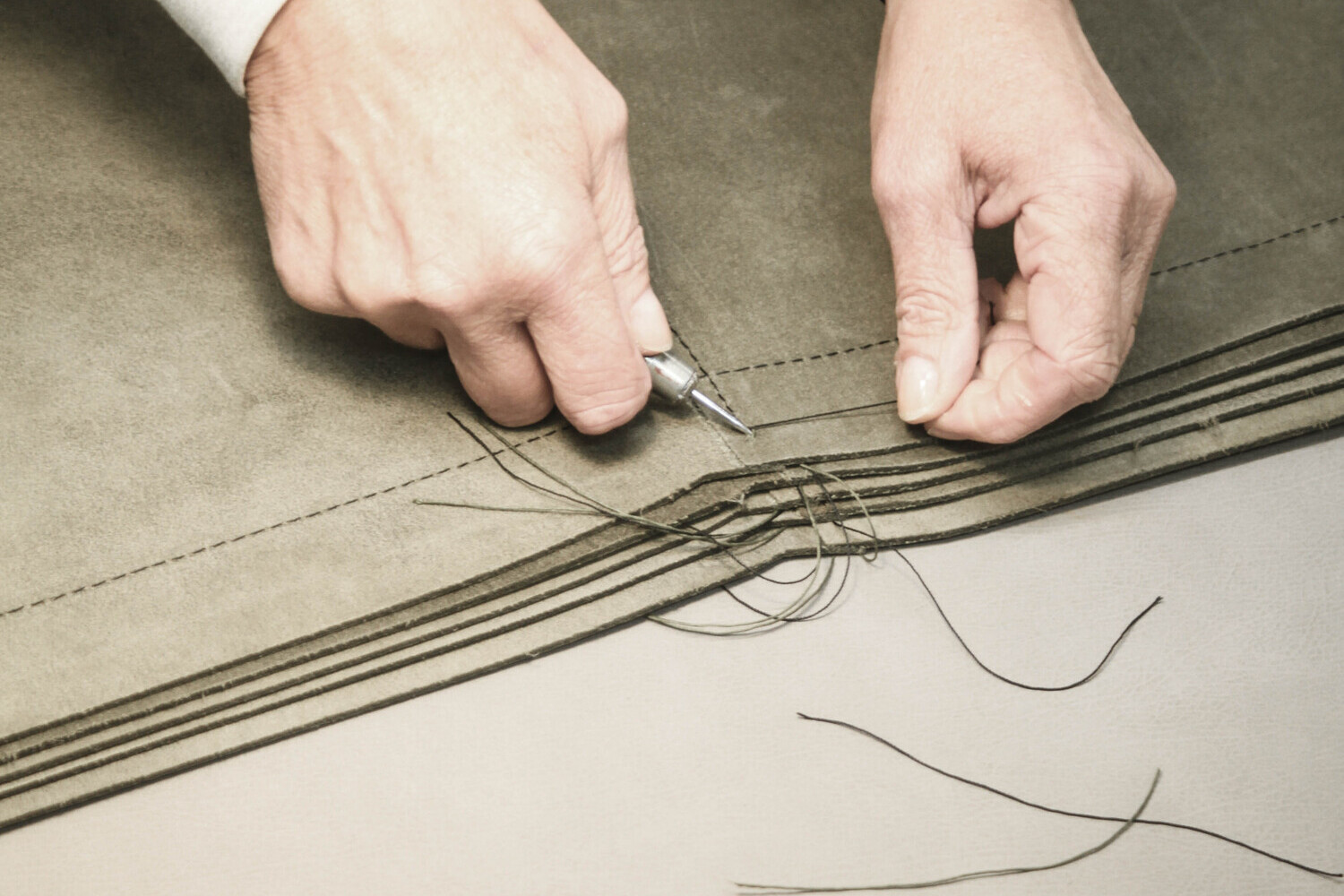

Sewing

the care of “handmade craftsmanship”

Each production batch, previously cut, is passed into the hands of skilled seamstresses who, with expertise and experience, align the individual leather pieces to create the chair’s upholstery.

Thanks to a wide range of sewing machines, we can select the ideal stitching type for each model, ensuring unique details and a high-quality finish.

Professional stitching on various materials

High-quality finishes

Tailored details

Hand-made in Italy

Venetian artisanal excellence

Our hands are the first and most valuable tool of our work. With a deep understanding of leather and hide, we combine tradition and artisanal processing techniques to upholster frames and shells made of metal, wood, or plastic with natural and precious materials.

The skill of our artisans, combined with a constant pursuit of perfection, ensures the highest quality of the finished product, guaranteed by careful and ongoing checks at every stage of production.

Reliability from design to deliverya

Dialogue

We find the right solution for every project by engaging in dialogue with designers and creating a tailor-made solution together with them.

Customer Support

Product refinement is a service available at every stage of production, from the initial prototype to ongoing improvements during the process.

We pursue perfection in every detail.

Selected suppliers

Quality control

The raw material (leather or hide) and every step of the processing are subjected to continuous checks to ensure the quality of the finished product.

Respect for delivery times

Respecting the deadlines agreed upon with the client has always been one of our priorities.

Cutting and handcrafting

Cutting and the processes carried out strictly by hand are of fundamental importance in bringing to life a handcrafted product, unique in its kind.

Hot thread sealing

The hot thread sealing ensures durability and quality of the finishes: quality is seen in the details.

Customizable

The final touch of style to make your project unique and inimitable, with a personalized signature.